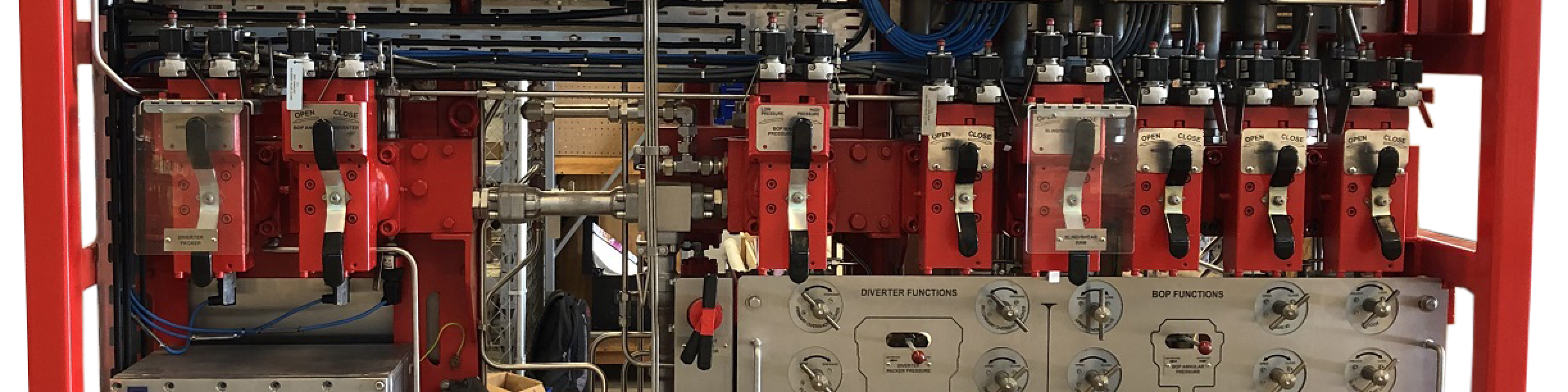

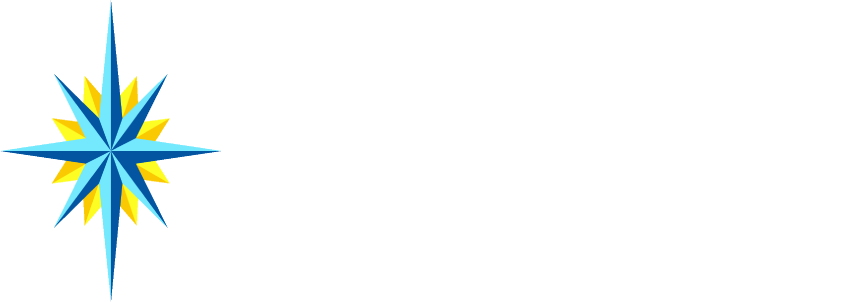

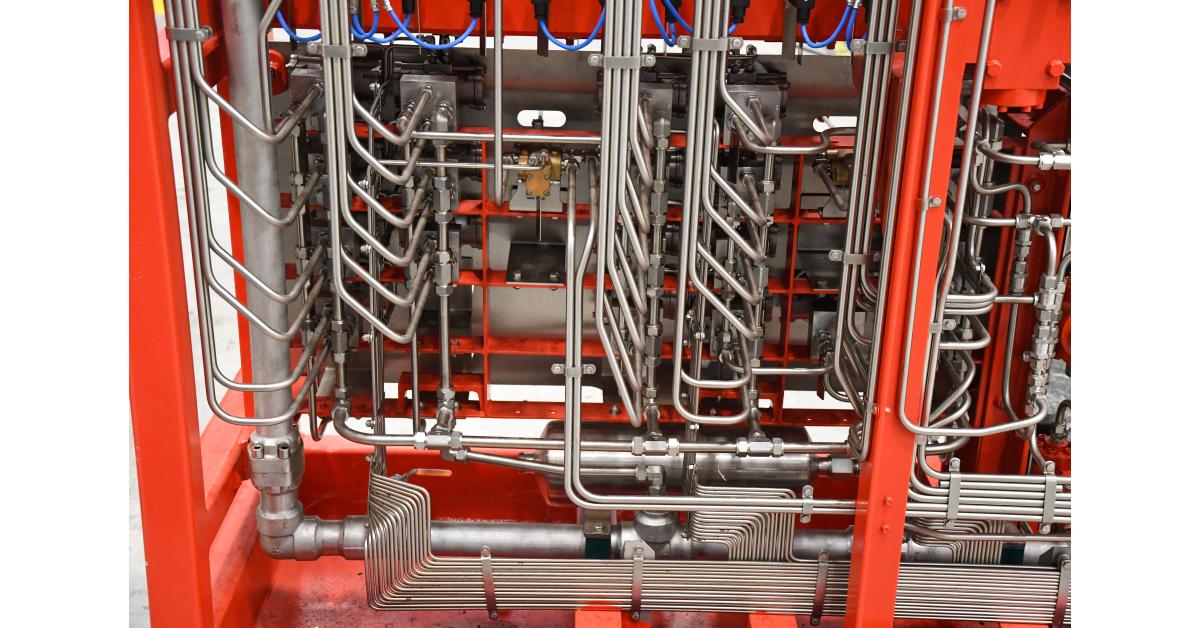

BOP & Diverter Hydraulic Control Manifold

Project Description: BOP & Diverter Hydraulic Control Manifold

Project Overview: Designed to operate a 18-3/4” - 15K BOP Stack Diverter

Specs:

- Footprint: 8’-8” L x 2’6” W x 7’-8 5/8” H

- Design Pressure: 5,000 psi

- Function Count:

- (3) 1-1/2 Functions

- (4) 1” Functions

- (20) Panel Mounted Functions

Key Design Features:

- Compact design = reduced footprint of similar systems

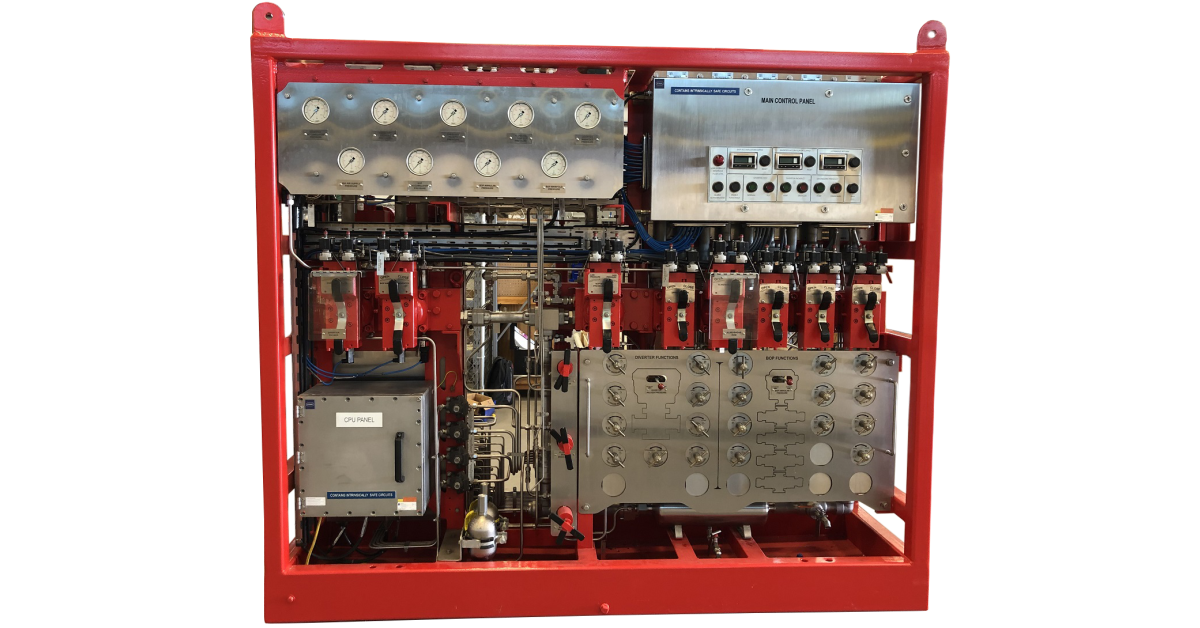

- Integrated Manifold

- Combination of control valves, actuators, solenoid valves, pressure switches and regulators integrated into a single valve manifold

- Allows for interchangeability between 1” a 1 1/2” control valves

- Maintenance

- Valve bodies and regulators can be easily accessed for removal or maintenance

- Manifold porting eliminates tubing required for sensing lines, which reduces leak paths

- Intrinsically Safe DesignIS remote I/O and end devices simplify installation and maintenance

- Utilizes 5,000 psi incoming pressure and regulates to required pressures for BOP/Diverter circuits

- Configurable valve panel assembly for multiple ¼” and ½” control valve arrangements

- Diverter automatic sequence via PLC, eliminating pneumatic logic in similar systems

- ATEX Zone 1 IIB T3 Area Classification

Project Applicable Standards:

- API 16D

- ASME B31.3

- CE (including 2014/34/EU)

- DNVGL-OS-E101

- IEC 61892

- NORSOK D-001 / E-001 / Z-010/ S-002 / M-501